Gobble Gripper

During the last year of my PhD I took a semester off to do a robotics residency at Google X where I joined a team working on improving plastic waste sorting in material recovery facilities. At the time, my assignment was to improve the gripping reliability of 6DOF industrial robots. The task was originally intended to involve using a depth map of target objects to improve the angle of approach from a suction gripper. After some analysis, however, I identified some unique characteristic of this problem that differentiated if from more traditional pick and place robotics tasks:

Trash sorting is dirty and the target objects are highly unstructured

There are no restrictions on crushing or squeezing the target object

Goal is to maximize volume throughput, not successful grasp rate

Therefore, I identified that the largest bottleneck was actually in traversal between target objects and sorting bins, rather than in grip reliability. My solution, was to design a novel "swallowing gripper" that used dedicated hardware to separate the traversal and sorting into separate hardware. The designed system was optimized for a straight down angle of approach, took advantage of the downward pressure of the arm to begin the "swallowing" action, and was able to reliably grasp rigid and non-rigid plastics quite reliably.

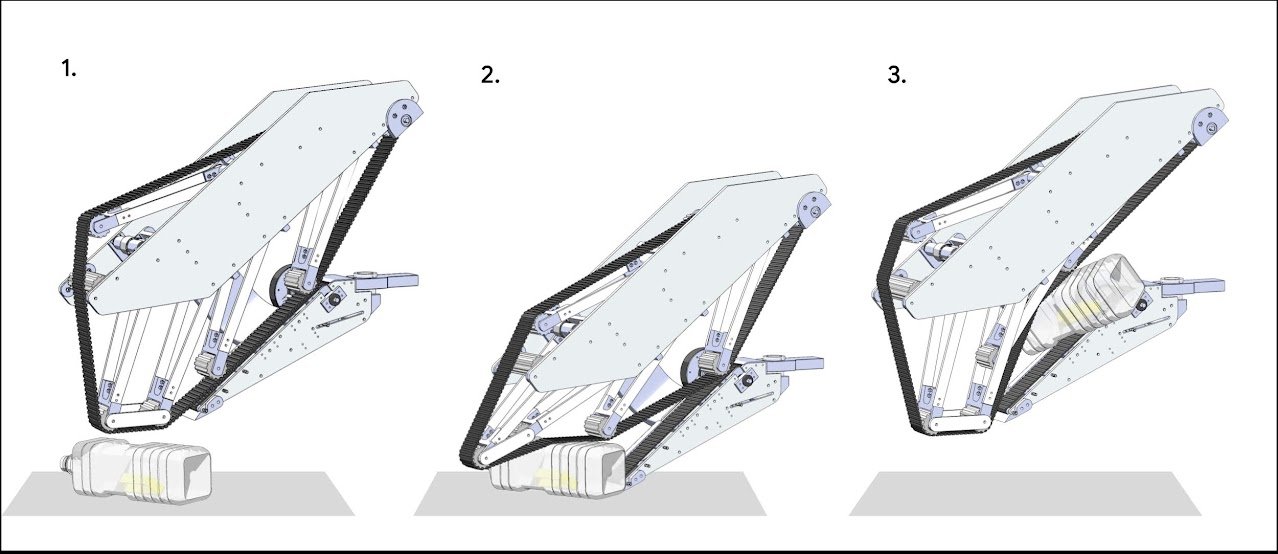

1. The gobble gripper is moved above a target object.

2. The gripper is brought down on top of the object. The four bar linkages in the leading “teeth” are designed such that the downward motion coaxes the target object into the mouth of the gripper.

3. A pair of tracked belts on the upper and lower jaws draw the object into the throat where it is sorted, all the while the gripper begins to traverse to the next target.

Prototype of the Gobble Gripper mounted to a 4 bar linkage to mimic presentation by a gantry or 6DOF arm. Design is able to successfully swallow slimy crushed plastics of varying sizes.

It works extremely well on non-rigid plastics as well! Jams can be detected by monitoring motor impedance and the belts reversed to “vomit” the stuck objects back out.